A spray foam rig is a sophisticated mobile factory, bringing together a suite of specialized equipment to transform raw chemicals into powerful insulation. Whether you're new to the industry or looking to upgrade, understanding the basic components of these rigs is fundamental to making informed decisions and ensuring safe, efficient operations.

Let's break down the key elements that make up a functional spray foam insulation rig:

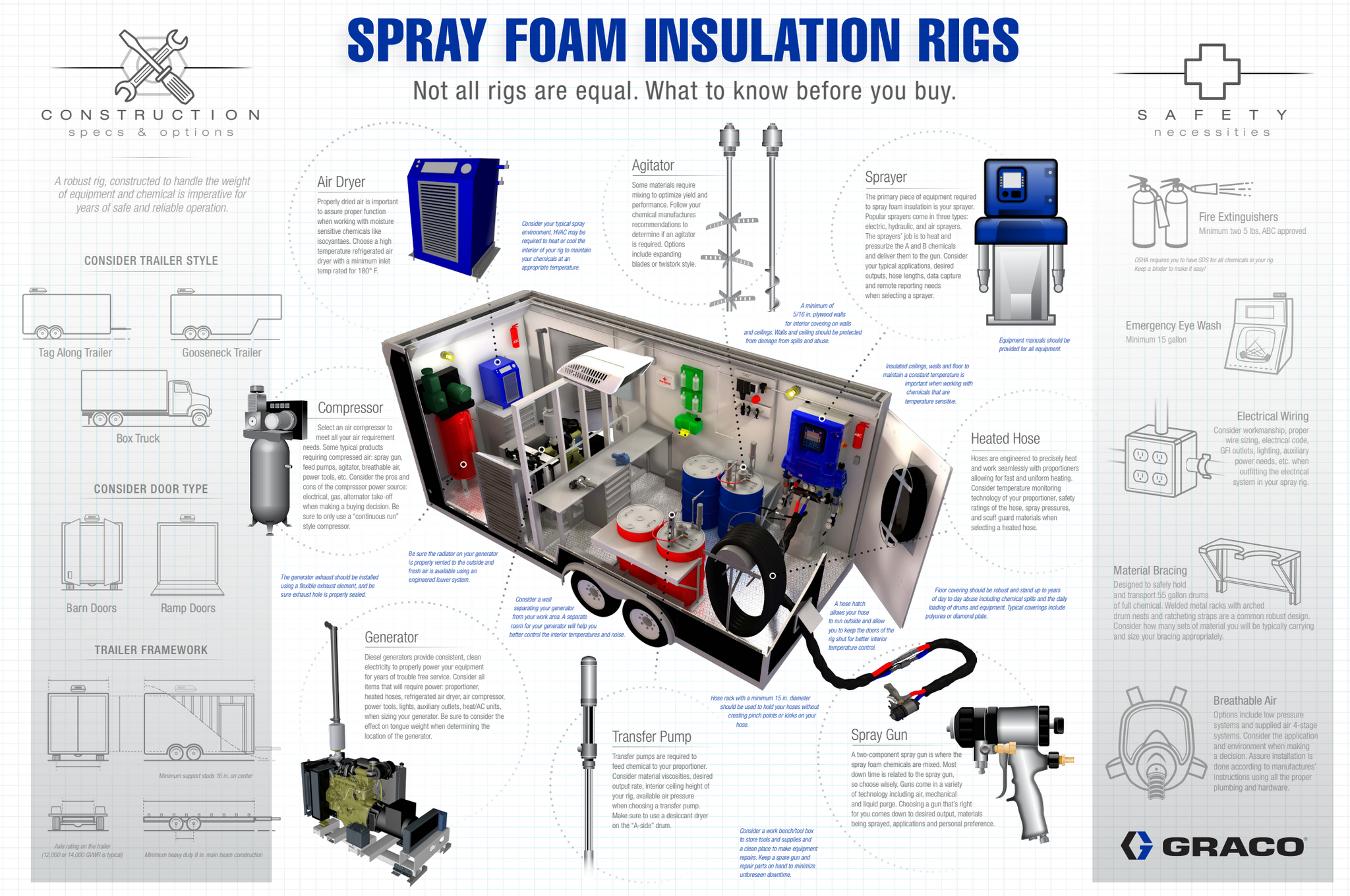

Often considered the "heart" of the rig, the proportioner, also known as the sprayer, is responsible for accurately heating and metering the A and B chemical components of spray foam. It then delivers these heated and pressurized materials through hoses to the spray gun, where they mix and react. When choosing a proportioner, consider your typical applications, desired output (how many pounds per minute you need to spray), and the length and diameter of the heated hoses you'll be using.

Transfer pumps are crucial for moving the viscous A and B chemicals from their drums or totes to the proportioner. They ensure a consistent and reliable supply of material, which is vital for maintaining proper chemical ratios and spray quality. When selecting transfer pumps, consider the container size (drums or totes) and the overall ceiling height of your rig.

Spray foam guns and certain auxiliary equipment rely on a steady supply of compressed air. The air compressor powers the transfer pumps, agitates materials in some systems, and atomizes chemicals at the spray gun. It's essential to select an air compressor that meets the CFM (cubic feet per minute) requirements of your spray gun and other air-powered tools.

Moisture in compressed air can wreak havoc on your spray foam equipment and compromise spray quality. An air dryer, typically a desiccant dryer, removes moisture from the compressed air supply, ensuring optimal function of your system and prolonging equipment life.

Your rig's entire electrical system, from the proportioner to the lights, relies on a robust power source. Diesel generators are a common choice, providing consistent, clean electricity to properly power all components. The generator needs to be sized to handle the combined power requirements of your proportioner, compressor, transfer pumps, lights, auxiliary outlets, and heating/AC units. Proper ventilation for the generator is also critical.

Maintaining the correct temperature of the A and B components as they travel from the proportioner to the gun is paramount for proper chemical reaction and foam quality. Heated hoses ensure fast and uniform heating along their entire length. Some systems also offer material temperature monitoring directly from the proportioner, allowing you to fine-tune your process..

This is where the magic happens – the spray gun is where the A and B components mix and are applied to the substrate. Choosing a gun that matches your system's output is critical for consistent spray patterns and optimal material yield. Spray foam chemicals are abrasive and sticky, so selecting a durable, easy-to-maintain gun is essential.

Some spray foam materials require constant agitation to prevent settling or separation of components. An agitator, often found in the B-side drum, ensures uniform material consistency, which is vital for consistent spray performance. Always follow your chemical manufacturer's recommendations regarding agitation.

The trailer itself is more than just a shell; it's the mobile workshop that houses all your equipment.

No rig is complete without a comprehensive suite of safety equipment. This includes:

By understanding each of these components and how they interact, you'll be well-equipped to specify, build, or purchase a spray foam rig that meets your business's demands and ensures professional results on every job.

The Truth About Spray Foam Roofing Warranties: What Every Contractor Needs to Know